Rayburn Tech Details

Please note the site preparations must be carried out before the fitting of the appliance

1. FLUE

The existing chimney is to be lined using 5″ flexible liner. Internal and external prefabricated flue to be 5″ double insulated (SM). Flue may exit horizontally or vertically from the RAYBURN.

We recommend that an anti-down draught cowl be used. The flue box on a rayburn supreme is on the right hand side- other rayburns on either side.

We strongly recommend a verdette cowl be fitted to your existing chimney.

2. ELECTRIC SUPPLY

This applies only to RAYBURN SUPREME. The fan-assisted burner requires a 240-volt supply and is fused at 3 amps.

3. VENTILATION

A permanent air vent with a minimum effective area of 5″ square (or the cross sectional area of the flue pipe, whichever is greater) should be provided.

4. FUEL

28 second heating oil. Feed pipe to RAYBURN is 10mm.

The oil control valve is situated on the opposite side of the flue, but may be sited up to five foot away. It is approxatly 5″ wide.

The fuel supply must be ready to turn on.

New regulations (BS5410) now states that a remote acting fire valve (eg, KKB) must protect all oil supply lines. The fire valve must be positioned outside the building where the oil enters the building, with the sensor near the Rayburn.

Get In Touch

5. HOT WATER & CENTRAL HEATING

All RAYBURNS with hot water facility MUST BE CONNECTED TO A GRAVITY FLOW SYSTEM (which must be indirect) with a 40 gallon hot water cylinder.

Central heating models, if fully pumped, will still need a separate gravity flow pipe in case of pump failure. The Rayburn Supreme has a maximum b.t.u output of 40,000 which we suggest is equivalent to approximately 8 single radiators. It can only be controlled by timing the central heating pump.

The 100sq ft model is fully manual with no need for electrical connection a central heating system. It is capable of heating 4 to 5 single radiators (100 square feet).

Both models should be fitted with either a flow pipe or hot water cylinder thermostat to switch on pump if water exceeds a certain temperature.

Water pipes exit from the opposite side to the flue. The hot water tank must be no further than 18 feet away, otherwise heat efficiency may be lost.

Pipe size is 28mm. Dimensions for flow and return pipes on application.

Note that the central heating models will also supply domestic hot water.

6. PLINTH

The cooker should be positioned on a level base of non-combustible material. Rayburn supreme-depth to be 23″ and the width to be 35″ while Rayburn royal-depth to be 20″ and width to be 33″. The height is optional.

7. FITTING COST

Our experienced and trained fitters carry out installation and the cost includes labour, all copper and brass fittings, plumbing and fittings but NOT the cost of any vitreous enamel flue pipe. And a further £50+VAT for the water, providing the water pipes are beside cooker. We would expect to arrive to find a fully prepared site i.e. that the chimney/flue is lined, the oil feed pipe is ready, the water pipes are ready, the base/plinth is prepared and that there is an oil supply. The cost of commissioning is £200+VAT.

OUR FITTING CHARGE DOES NOT INCLUDE FLUE MATERIALS, BUILDING.

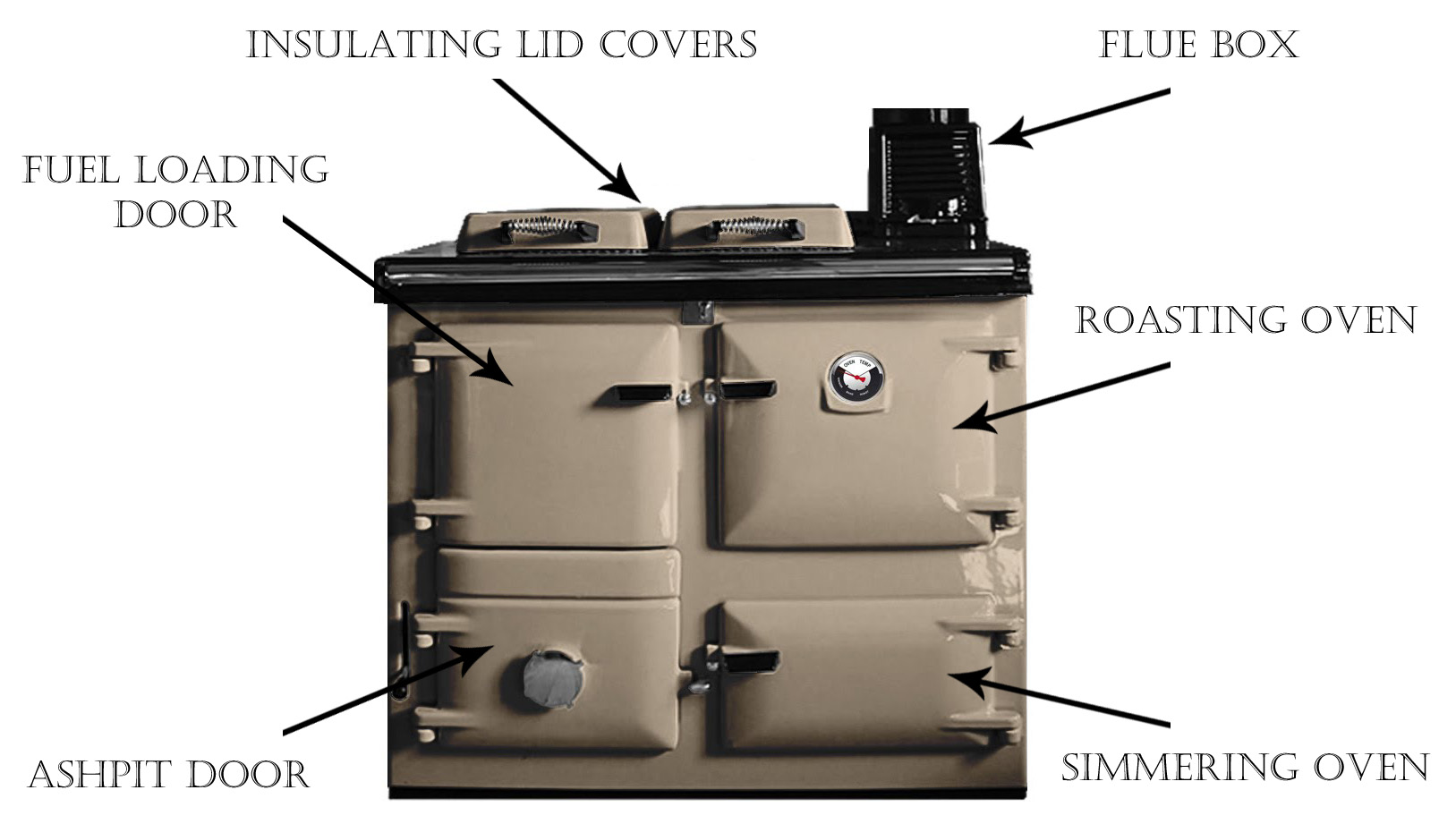

Please click on the thumbnail to view the oven layout of the Rayburn